The Hidden Costs of Low-Quality Industrial Products: Investing in Long- Term Success

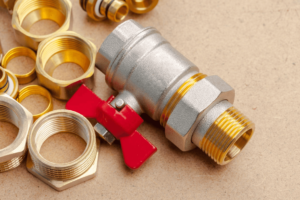

In the fast-paced world of heavy-duty machinery and industrial equipment, the choice between

high-quality and low-quality products can have a profound impact on the overall performance,

longevity, and profitability of a business. In an era where cost considerations often dominate

decision-making processes, it is not uncommon for customers to prioritize price over quality

when selecting industrial components such as hoses, valves, hose fittings, couplings, and other

accessories.

However, the true cost of this approach is often underestimated, as the ramifications of

investing in subpar products can manifest in unexpected and costly ways.

In this article, we will explore the critical differences between high-quality and low-quality

industrial products. We will delve into the long-term benefits of choosing superior products,

emphasizing on how this decision can drive return on investment (ROI), enhance business

performance, and contribute to overall profitability.

The Allure of Low Prices

One of the prevailing challenges in the industrial sector is the pervasive mindset that prioritizes

immediate cost savings over long-term value. This mindset is particularly evident when it comes

to purchasing industrial products, where customers may be tempted by lower price points

without fully considering the implications of sacrificing quality.

Low-quality industrial products often flood the market, and some manufacturers go to great

lengths to mislead customers. One common tactic is the misrepresentation of product origin,

with items claiming to be from reputable regions such as Europe or the United States where

quality assurance and licensing is paramount, when, in reality, they are manufactured

elsewhere. This practice can be misleading, as customers may associate certain regions with

high-quality craftsmanship and advanced technology.

While customers think that they are saving money by purchasing lower cost items upfront,

through time and usage, they begin to see that the products are not what they claim to be.

The True Cost of Low Quality

While the allure of lower prices may be enticing, the long-term costs associated with low-quality

industrial products can far outweigh the initial savings. In the context of heavy-duty machinery,

components such as hoses, valves, fittings, and couplings, play a pivotal role in ensuring

seamless operations. Choosing subpar products can lead to a range of issues, including:

- Safety Concerns: Inadequate industrial products may compromise safety standards,

posing risks to both equipment and personnel. This can lead to accidents, injuries, and

potential legal liabilities. - Reduced Performance: Low-quality hoses and valves may not meet the necessary

specifications for heavy-duty applications, leading to decreased overall performance and

efficiency. - Frequent Replacements: Inferior materials and construction often result in a shorter

lifespan for industrial components. This can lead to frequent replacements, disrupting

operations and incurring additional costs over time. - Downtime and Maintenance Costs: Equipment failures due to substandard

components can result in unplanned downtime and increased maintenance costs. This

not only affects productivity but also places a strain on overall business operations.

The Long-Term Benefits of High-Quality Industrial Products

Investing in high-quality industrial products may require a higher upfront cost, but the long-term benefits far outweigh the immediate savings associated with low-quality alternatives.

Here are some key advantages of choosing superior products for heavy-duty machinery:

-

Enhanced Durability: High-quality materials and precise manufacturing processes contribute to the durability of industrial components. This results in longer lifespans and reduces the need for frequent replacements.

-

Optimized Performance: Superior design and construction ensure that industrial products meet or exceed performance specifications. This optimization contributes to the overall efficiency and reliability of heavy-duty machinery.

-

Reduced Downtime: The reliability of high-quality components translates to reduced downtime, minimizing disruptions to operations and enhancing overall productivity.

-

Lower Total Cost of Ownership: While the initial investment may be higher, the lower maintenance and replacement costs associated with high-quality products result in a lower total cost of ownership over the lifespan of the equipment.

-

Contribution to Sustainability: High-quality industrial products often adhere to environmental and sustainability standards. This not only benefits the planet but also aligns with the growing demand for eco-friendly practices in the industrial sector.

Identifying Quality and Legitimate Products

Given the prevalence of misleading claims and counterfeit products, it is crucial for customers to develop the ability to distinguish between high-quality, legitimate industrial components and their subpar counterparts.

Here are some key tips to help customers make informed decisions:

-

Manufacturer Reputation: Research the reputation of the manufacturer. Established and reputable companies are more likely to produce high-quality products, and their track record can be a reliable indicator of reliability.

-

Certifications and Standards: Legitimate industrial products often adhere to industry-specific certifications and standards. Look for certifications such as ISO 9001 for quality management systems or other industry-specific standards.

-

Material Specifications: Understand the material specifications of the hoses, valves, fittings, couplings, and industrial components you are considering. High-quality materials contribute to durability and overall performance of the entire equipment.

-

Traceability: Legitimate manufacturers provide traceability for their products, allowing customers to trace the origin and production details. This transparency is a hallmark of quality. Request for a Certificate of Origin to verify the information provided by the manufacturer with regards to a specific product.

-

Third-Party Testing: Products that undergo third-party testing for performance and reliability are more likely to meet or exceed industry standards. Look for evidence of independent testing.

-

Review Customer Feedback: Read customer reviews and testimonials to gauge the real-world performance of the industrial products. Honest feedback from other businesses can provide valuable insights.

-

Beware of Unrealistic Claims: Be wary of products that make unrealistic claims or promises. If something seems too good to be true, it likely is. Verify claims through reliable sources before making a purchase.

In the complex landscape of industrial machinery, the choice between high-quality and low-quality components is a decision that reverberates throughout the entire business operation. While the allure of lower prices may be enticing, the long-term costs associated with inferior products can have detrimental effects on performance, reliability, and overall profitability.

Investing in high-quality industrial products, including hoses, valves, hose fittings, couplings, and other accessories, is an investment in the future success of a business. By prioritizing durability, performance, and adherence to standards, businesses can minimize downtime, reduce maintenance costs, and optimize the efficiency of their heavy-duty machinery.

To navigate the marketplace successfully, customers must develop a keen ability to identify quality and legitimate products amidst a sea of options. By considering factors such as manufacturer reputation, certifications, material specifications, traceability, third-party testing, and customer feedback, businesses can make informed decisions that contribute to their long-term success in the industrial sector.

In the end, the choice between high-quality and low-quality industrial products is not just a financial decision—it is an investment in the reliability, safety, and sustainability of the entire business operation.

AlBinali Industrial Supplier is the commercial arm of Abdulla M. AlBinali & Partners- the leading industrial supplier in Saudi Arabia. We aim to bring you a wide selection of authentic, top quality products from the most renowned manufacturing brands across the globe. In our 5 centrally-located showrooms, we carry various industrial supplies including hoses, valves, hose fittings, couplings, and other accessories.

Find out more about what we offer and where we are located: www.albinalico.com